My dad was a boomer, he insisted that Phillips heads didn’t used to strip out this bad and it’s just that everyone switched to making shit cheap screws out of shit cheap material. He also lived to see the enshittification of appliances from something you buy once in your life to something you buy every five years (at least, according to the warranty) with a nifty galifty payment plan. Walking into home Depot instantly radicalized him.

I think I’m with your boomer dad on that, though. Screws are increasingly cheaper and shoddier than they use to be, and probably because of the materials used are light and easy to produce. Now, the boomers blame “them dang cheap Chinese screws” but we all know it’s enshittification for the sake of profit (which I guess can and would include globalization of supply chains).

True, but on the other hand, the drills or impact drivers are also getting stronger and stronger, so it’s easier to mess up a screw. And then there’s the driver bits, they’re so bad these days that every new box of screws comes with a free bit.

I still hand screw things and they still break even with the right size driver, haha. But yes, those titanium coated bits make quick work of aluminum screws.

Your dad is right. I never used to strip out Robertson deck screws. Now, if you’re lucky enough to get a screw in, the chances of getting it out unstripped approaches nil. If I search around and find good brands like Richileu, I don’t have that problem. The shit Chinesium screws at Home Depot today are horrendous.

I’m not positive that this comment is Canadian enough.

i’d believe it to be honest, problem is phillips is still shit. You put ANY torque into them, you’re gonna need to put a LOT of back pressure on them. Which is the primary reason they tend to strip anyway, inadequate back pressure, causing the bit to slip, getting a purchase on the fragile little corners, and then fucking DELETING them from existence.

I am old enough to remember when they only had manual screw drivers and thicker wood screws that needed to be pre-drilled and lubed with soap.

Go buy a modern “cheap” wood screw. Not a deck screw. An actual wood screw. Pre-drill the correct size hole, including the countersink, and use the correct size manual Phillips screwdriver. You will never strip out the screws.

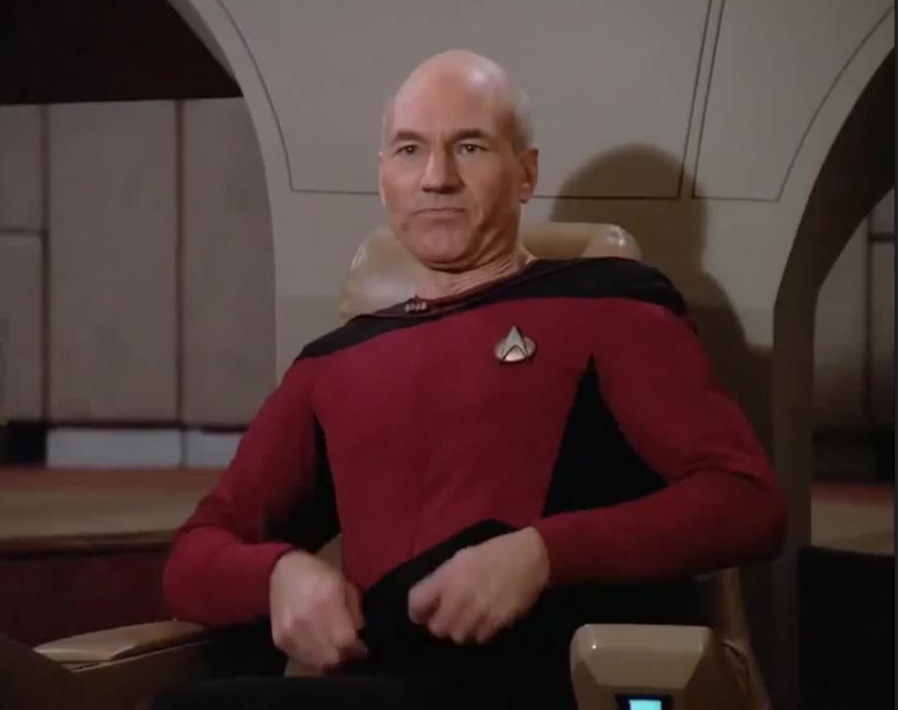

Now take a 500 RPM impact driver that has almost enough torque to remove lug nuts, a worn or wrong size bit, and a thin shank screw that was only designed to hold down deck boards and the slightest slip or misalignment and have this photo.

We all do it because it is fast/easy. Just understand that you are doing things the convenient way instead of the right way, and you have to expect the stuff to sometimes not work aa advertised because of it.

I’m a millennial, I don’t really recall phillips screws getting universally worse over my lifetime. I’ve torn the drive out of a LOT of them over the last three decades.

What I have seen is Phillips holding still while the rest of screwology improves around them. Take an impact driver and blast in a few 3.5" #10 Torx deck screws, then try to install a Phillips head screw and see if you can keep the word “bullshit” from coming out of your mouth.

There’s also the issues of Pozidriv and JIS, which both superficially resemble Phillips but are different and work VERY poorly if turned with a Phillips driver.

Home appliance enshittification is real though. I’m running my Kenmore 80 series for as long as I can.

Millennial here, too. Phillips screws have been made of fucking cobwebs and wet tissue as far as I remember too.

total torx supremacy

Torx gang reporting in 👌👍

One of the IT guys at my work is really good at stripping torx, but that’s because he uses a driver a couple sizes too small.

That’s just… Wow.

the sizes are definetley hard to figure out, but the “if it wiggles, it’s too small” rule applies to torx as well.

your mistake is using philips

Not always a choice we get to make, but I see your point

Yeah, Torx is the way to go!

torx 4 life

Nah, Robertson

Thing is, I wouldn’t even know where to get those. Torx is readily available, often even at an Aldi.

They’re everywhere in Canada. Just depends where you live tbh.

Partially stripped phillips? Grab a flathead screwdriver close to the same size and use a hammer to tap it down into the screw head. Twist it out while pushing down.

I turn screws as part of my job and can’t eait to try this

+1 for torx. Have actually snapped screw shafts with those

That’s the whole difference between torx vs Phillips.

Theoretically, you should never break a screw shaft with Phillips because they are designed to cam out before enough torque is applied to break the shaft of the screw.

It’s supposed to be a feature

Still gonna use torx because once a philips cams out the screw as well ss the tool tip is useless

The poor man’s Robertson

Go back to Canada!

Who needs more than 4 sides anyway?

honestly torx is still garbage. the tiny ones on the bottom of tech products that get cemented in still strip like nobody’s business.

phillips doesn’t scale any better. i’m actually glad whenever i see torx on small devices instead.

Idk man, I’ve been working IT for 10 years and have never stripped a torx. Didn’t know it was possible

Tech products often use stainless steel bolts, which are a lot softer than a normal steel

alrighty so torx screws are just shit in most cases you encounter them

I’d say by sheer count the majority of Torx screws I’ve encountered have been for deck boards, not tiny tech screws. And they were excellent.

Never have for me. I dont turn til fully seated

I ain’t screwing with half my ass off my seat

Coming in clutch

+1 for torx being available in america. +1 for robertson existing at all.

pozidriv is pretty cool, but annoying to use since people confuse it with phillips all the time so you end up with a lot of stripped screws.

torx is the way to go. their sizing is odd, but it transfers torque well and is wear-resistant.

Double hex and triple square just have to be just as bad as all the Phillips variants. I can’t see that being a reliable shape for a screw

My GTI had triple-square bolts for the seats. The bolts were maybe 1/2" diameter, and I was able to comfortably get a lot of torque on them. Weird design though, and can’t imagine it holding up on smaller, softer screws

Robertson obviously.

Oh, the heads not quite flush, lemme give it juuuuuuust a bit moreahhhhfuck

Maybe if I just stop, align it perfectly, put more pressure behind it and gently start tuuuAHHHFUCKOFF!!!

Mhmm EasyGrip

Phillips screws “strip” by design. it’s a method to prevent over-torquing the screw.

I personally buy torx screws.

Half my laptop’s screws are like that and it drives me insane trying to open it now.

Laptop screws are usually JIS instead of Philips. Get a JIS screwdriver and you won’t have that issue in the future.

Or just stop screwing your laptop and go jis somewhere else

I’m impressed you managed to thread that joke in here.

It was right there in the groove, you just had to send it.

Ugh, I clearly don’t fit here. Going to go for a drive.

Come in, it’s pretty simple… machine. Fuck.

I don’t think there’s enough screw puns to keep going, we’ll have to start rotating some of them back

Here’s a tip for anyone with this problem. Take an elastic band and place it over the devastated screw and try again.

I’ve tried this hundreds of times and it’s never worked.

I posted it above, but the best way is to Dremel with a metal cutting blade to convert it to a flat head.

Source: I used to work for Home Depot and had to fix shit for people all the time.